The belleville will be in its flat position when the preload in the bolt equals the flat load 1 since the spring will be clamped between the flat joint an d the nut any additional torque applied to the nut will only stretch the bolt.

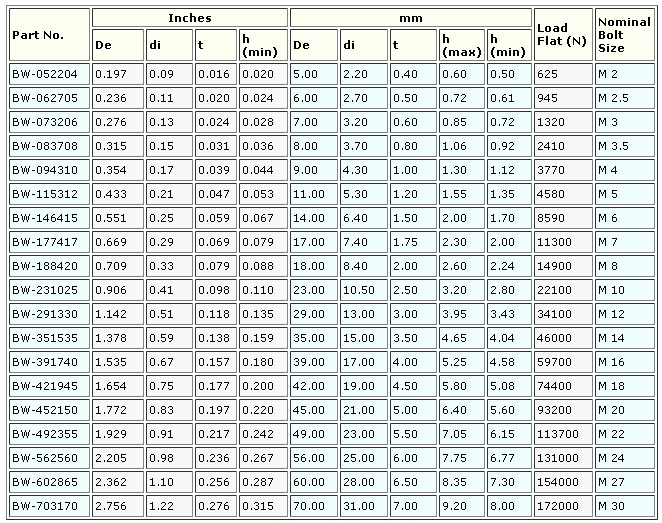

Belleville washer torque table.

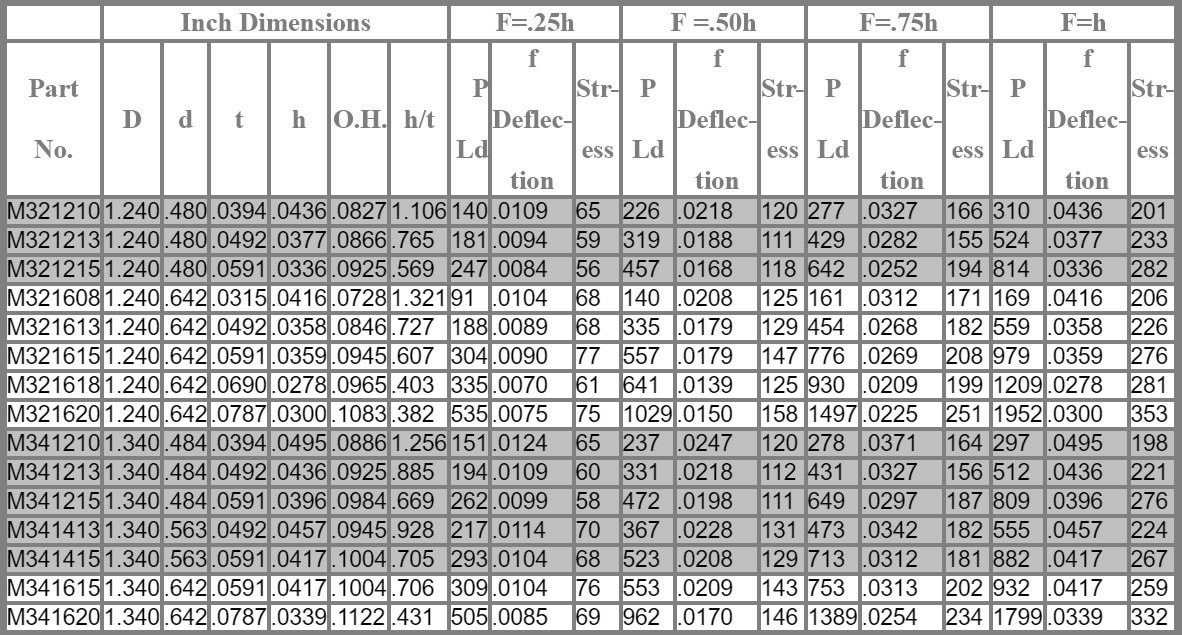

Calculation example multiple belleville washers may be stacked to modify the spring constant or amount of.

Clamp load is also known as preload or initial load in tension on bolt.

When tightening according to guidelines and with no deviation this is the pre stress achieved expressed as of yield point.

Torque calculation the widely accepted formula is as follows t k f d where k estimated nut friction factor t bolt torque d nominal bolt diameter.

This is the same with belleville washers.

Should you have any additional questions our engineering team here at belleville international is available for your convenience and can be reached by calling 877 235 5384.

G f ratio of yield point.

All stainless steel hardware stainless steel hardware with bronze nut dia.

5500 lbf belleville washer as supplied by sefcor.

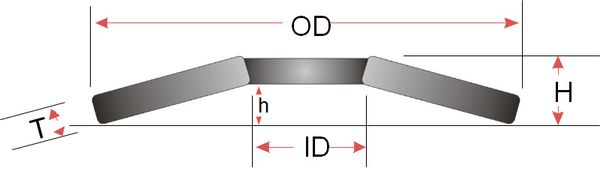

Belleville washers manufactured from steel strip are not scragged pre stressed during the manufacturing process and the inside and outside diameters of the disc.

Thread friction coefficients have theoretical values.

Silicon bronze hardware is not lubricated.

The belleville washer can then be added seamlessly and no modification to this torque value is needed.

1 spring is considered to be 1 in parallel 1 in series.

And p bolt clamp load developed by tightening.

The lee spring din belleville disc washer series offers metric disc spring washers to meet global demand for sizes specified by din 2093.

Lee spring also expand on size options past din 2093 s standard size tables made to din manufacturing and quality specifications to provide component flexibility for product designers.

So that the bolt and belleville washers work together make sure the torque for your belleville washers matches that of your bolts.

In lb ft lb n m in lb ft lb n m 1 2 540 45 61 660 55 75.

Again belleville washers are no exception.

μ th thread friction coefficient μ h under head friction coefficient 1 n 0 225 lb 1 nm 0 738 ft lb.

The values assume the following in addition to the information listed in the chart.

If you exceed a locking washer s torque by more than a few percent during assembly you destroy the locking washer.

D nominal bolt diameter.

Performance considerations a similar device is a wave washer.

Tightening torque values are calculated from the formula t kdp where t tightening torque.

Clamp load lb is calculated by arbitrarily assuming.

Cu c paste copper graphite paste molykote 1000 oil wd40 has been used.