For aluminum sheet metal the bending radius is greater than the thickness of the plate.

Bending force problem sheet metal.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

Minimum bending radius is a function of the ductility and thickness of the metal formed.

According to prabhakar et al.

Sheet metal part design bend allowance duration.

Due to the elasticity the bending angle of metal is slightly bigger than the angle required.

We are going to review three bending scenarios with three different bending angles.

The bend deduction is the amount the sheet metal will stretch when bent as measured from the outside edges of the bend.

Description of the bending force formula and a sample problem off the bending problems worksheet.

The notation used in the text l w differs from that used in the previous development b l.

Sheet metal bending is one of the most widely applied sheet metal forming operations.

The bend radius refers to the inside radius.

Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1.

The formed bend radius is dependent upon the dies used the material properties and the material thickness.

The bending force can be calculated from the sheet thickness die opening bend length and the ultimate tensile strength of the material.

Bending force requirement punch workpiece t die w force t sheet thickness w width of die opening l total length of bend into the page uts ultimate tensile strength of material 2 uts w lt f note.

The die ratio may be entered to calculate the die opening which is typically 6 to 18 times the sheet thickness.

Bending of sheet metal is one of the widely used in industrial process especially in automobile and aircraft industries sheet metal bending is one of the most widely applied sheet metal forming operation.

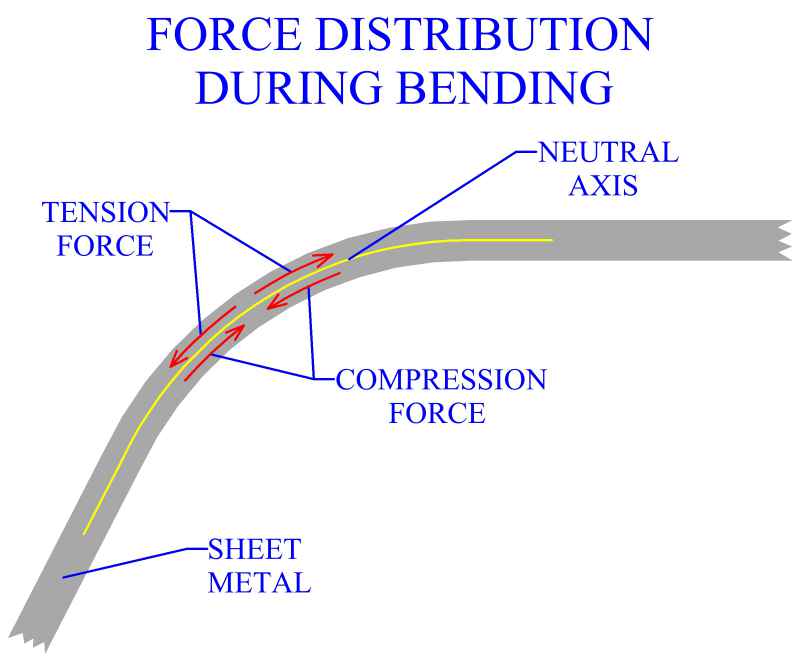

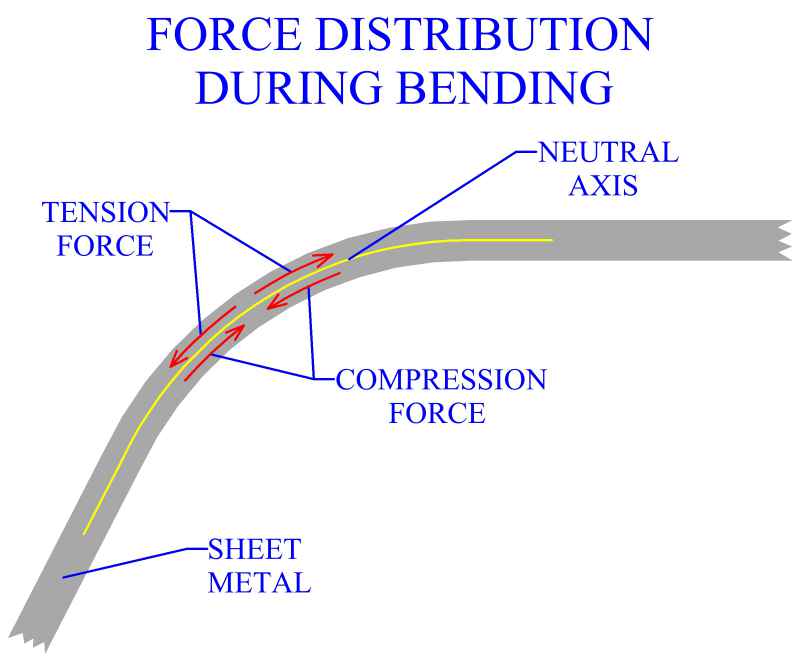

During the bending process of the sheet the material in the deformation zone is in a highly plastic deformation state and it is turned at an angle around the centerline.

This is done through the application of force on a workpiece.

The bending of the metal sheet is conducted in a metal processing workshop.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

To define the bend region and reduce the force required to bend a part out of sheet metal down to something you can handle without a brake press slots can be cut at the bending line to selectively.